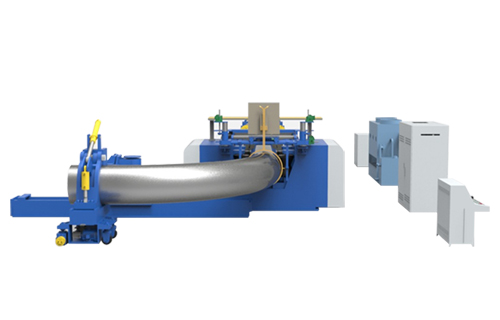

A specialized machine that uses an induction heating coil to locally heat a narrow section of a pipe while a swing arm bends it. This process is used for large-diameter or heavy-wall pipes (often for oil and gas pipelines) to minimize wall thinning and ovality during the bend.

Induction bending is a very efficient and precise bending technique using heat in order to bend tubes, pipes and sections. It takes over where cold bending methods meet their limitations. The combination of speed, local heat and cooling allows for bending even bigger profiles.

Induction heating pipe bending machine uses intermediate frequency induction heating to bend the workpiece under the condition of local heating. Compared with the general cold pipe bending machine, it not only does not need a complete set of special mold, and the volume of the machine only accounts for the same specification of cold pipe bending machine 1/3 ~ 1/2.

The process of intermediate frequency bending is to cover the bending part of the steel tube with an induction ring, use a mechanical rotary arm to catch the pipe head, and pass a high-density if current into the induction ring to heat the steel tube. When the temperature of the steel tube rises to the plastic state, the steel tube is pushed forward by mechanical thrust at the back end of the steel tube for bending. Simple process flow: namely side heating, side pushing, side bending, side cooling, finish bending control.

The straight pipe or section is placed in the machine bed by guiding it through three coils that match the shape of the profile and by gripping one end of the profile in the bending arm. The bending arm is set to the required radius.

Once the profile is in position the copper heating coil heats up to the required temperature (up to 1,100ºC) and creates a circumferential heated zone. The two adjacent coils with nozzles are cooling the profile by blowing cold air and spraying water on the surface. As the heating coil reaches the required temperature, the profile is gently pushed through the coils. The swing arm moves along with the profile and bends it in the required radius and shapes it into a bend.

Induction

| Size | Type | IF type | Cylinder size | PLC available |

| 6″ | YWG-159 | 200KW | ID 140 OD168 | NO |

| 8″ | YWG-219 | 200KW | ID 140 OD168 | NO |

| 12″ | YWG-325 | 250KW | ID180 OD219 | YES |

| 16″ | YWG-426 | 350KW | ID180 OD219 | YES |

| 20″ | YWG-530 | 400KW | ID180 OD219 | YES |

| 24″ | YWG-630 | 500KW | ID200 OD245 | YES |

| 28″ | YWG-720 | 600KW | ID200 OD245 | YES |

| 32″ | YWG-813 | 800KW | ID220 OD273 | YES |

| 36″ | YWG-914 | 800KW | ID250 OD299 | YES |

| 40″ | YWG-1020 | 800KW | ID250 OD299 | YES |

| 48″ | YWG-1020 | 1000KW | ID280 OD325 | YES |

| 56″ | YWG-1420 | 1000KW | ID280 OD325 | YES |

| 60″ | YWG-1520 | 1000KW | ID280 OD325 | YES |

| 64″ | YWG-1620 | 1000KW | ID320 OD377 | YES |

Get The Best Quote For Your Products